ADVANCED DUST FREE SOLUTION

Cleaner, Faster, Clever.

ULTRAVENT TECHNOLOGY

Advanced dust free solution

INDASA has developed a unique and highly advanced dust free sanding solution with the scope to transform the future of machine sanding. The extraction capacity of the new ULTRAVENT System virtually eliminates abrasive clogging, prolongs performance and provides a clean, healthy working environment.

The superior dust free sanding process produces a highly consistent finish, maximizes operator efficiency and optimizes bodyshop key performance indicators (KPI's).

ULTRAVENT SYSTEM

ULTRAVENT & Rhynogrip

Scroll down to explore our product lines designed with the ULTRAVENT technology

ULTRAVENT System

Discover the features and benefits of our advanced dust free solution.

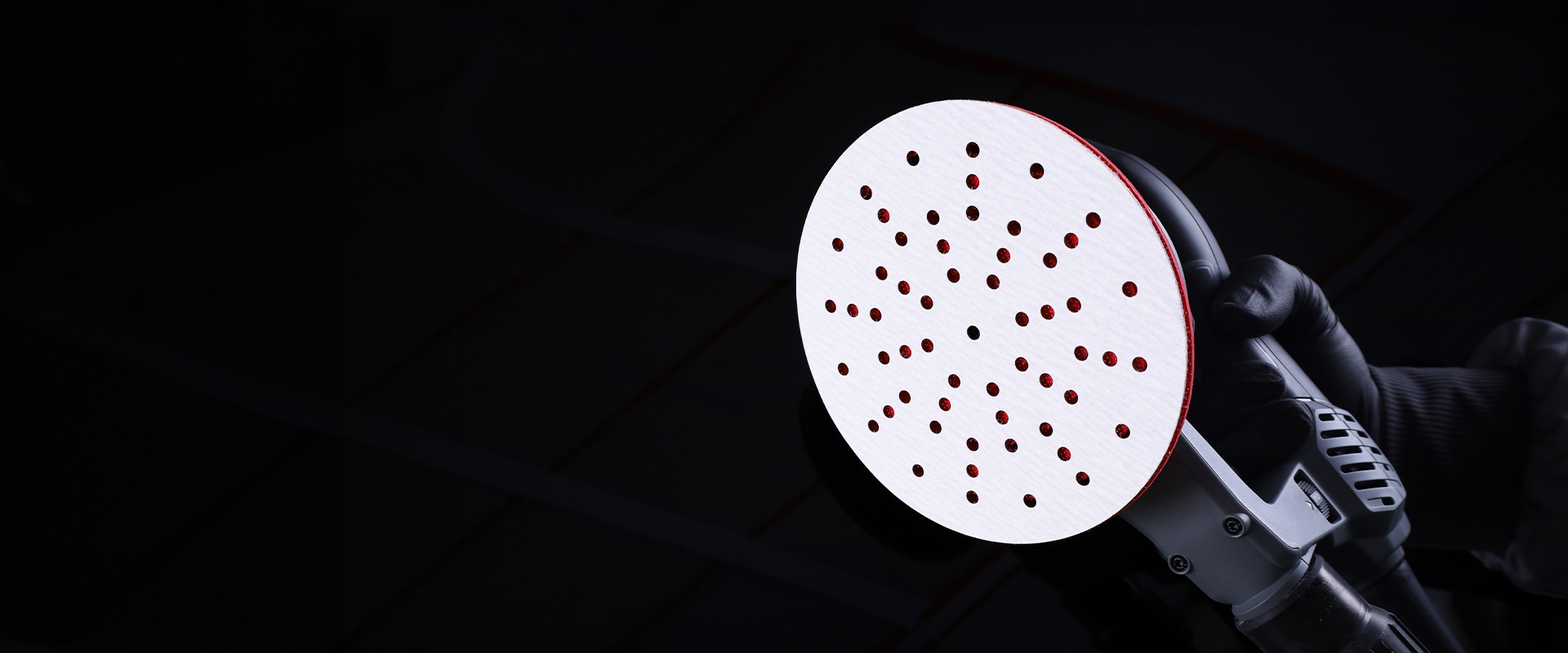

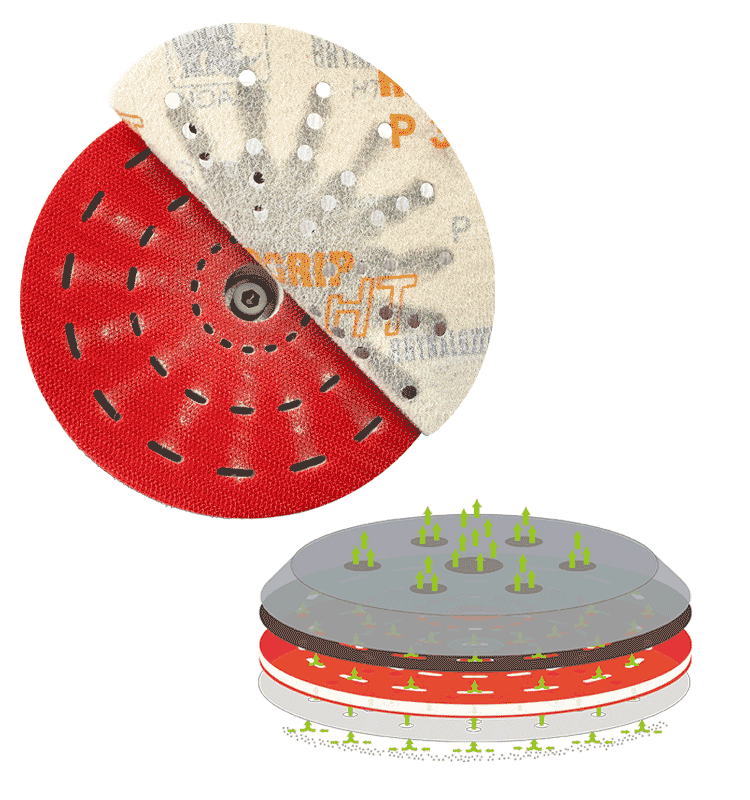

ULTRAVENT BACKING PAD

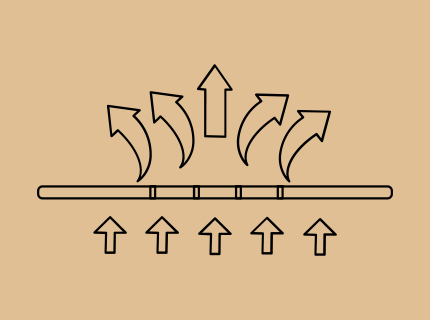

Unique vent channel

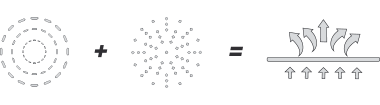

The unique vent channel configuration allows for a quick and easy application of the Rhynogrip disc to the pad.

The innovative design of the backing pad utilizes patented vent channels to maximize vacuum air flow.

ULTRAVENT DISCS

Performance and consistency of finish

The cleaner working environment helps keep dust contaminants out of the repair process.

The 21 hole configuration is applied to Rhynogrip discs in coarser grits P80-P180.

The 57 hole design is applied to Rhynogrip discs in the finer grits P220-P2000.

Abrasive loading is minimised while the cut is maintained at it's peak through-out the life of the disc.

.png)

ADVANTAGES

What makes the ULTRAVENT technology so unique?

Besides being fully compatible with Rhynogrip abrasive systems, our ULTRAVENT adds value by:

ADVANCED DUST FREE SOLUTION

Complementary products

Browse through our products associated with ULTRAVENT technology